Hydraulic Hammers

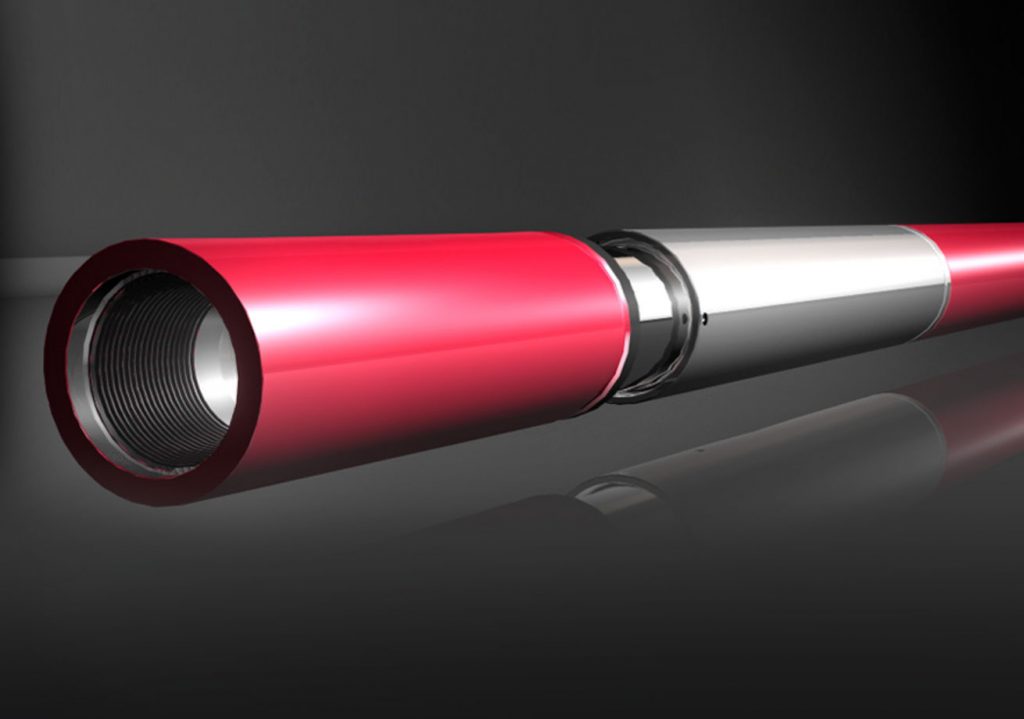

Double Acting Hydraulic Drilling Jar

The Wenzel Downhole Tools Double Acting Hydraulic Drilling Jar (HJDA) is a bi-directional drilling jar incorporating hydraulic delay without a latch mechanism. This jar will allow the operator to apply variable impact in both the up and down directions. The HJDA is intended for use in highly deviated or high friction wells, where conditions may prevent applying sufficient force to release a mechanical latch.

Built to strict CSA, API, and ASTM design, test, and manufacturing standards and supplied in long-length continuous spools or standard-length bars, our line pipe is simple and quick to install and deploy.

- The HJDA is hydraulically controlled and jars in both directions, with impact force controlled by the operator.

- Impact force is controlled by a metering device that ensures consistent delay times over the full range of operating temperatures.

- The HJDA operates via a simple up and down motion and is unaffected by right- or left-hand torque.

- Standard seals in the tool are effective to 250°F (120°C). The jar can be dressed with seals effective to 400°F (200°C) for hot hole environments, and 450°F (230°C) for extreme temperature environments. External sealing surfaces are tungsten carbide-coated to enhance wear and corrosion resistance.

Jarring Up

With the jar in the neutral position, apply the desired overpull in excess of the free string weight, starting the hydraulic delay sequence. At the end of the hydraulic delay, the jar will release causing an upward impact force.

If necessary, lower the drill string sufficiently to close the jar to the neutral position, ready to jar up again.

Jarring Down

- With the jar in the neutral position, lower the drill string to apply the desired down force, starting the hydraulic delay sequence. At the end of the hydraulic delay, the jar will release causing a downward impact force.

- If necessary, raise the drill string sufficiently to open the jar to the neutral position, ready to jar down again.