Coring

Coring Service provides a direct measurement of the formation of the earth's crust and provides critical information about the reservoir, through a soil sample. Our highest priority is to guarantee the quality of the samples through high-tech and innovative equipment and tools.

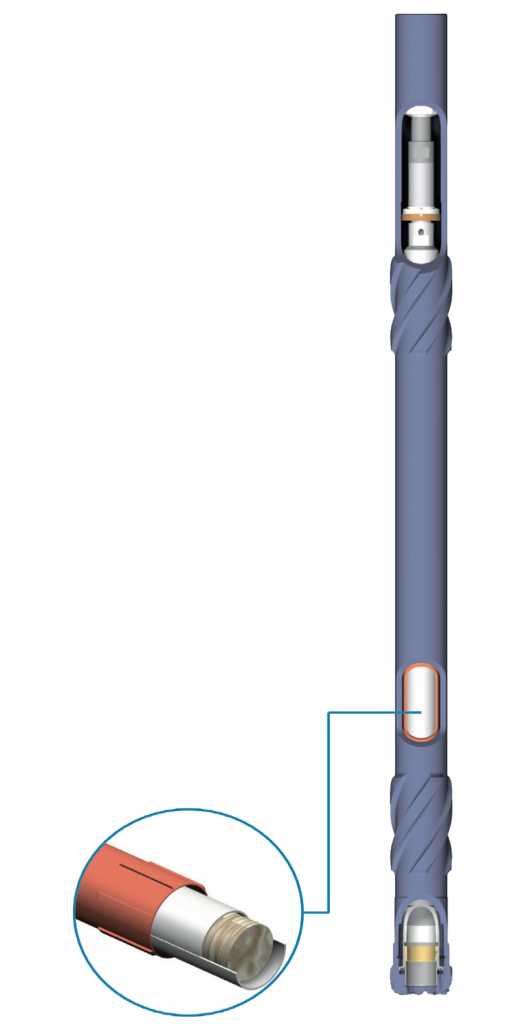

Background equipment

It has a 20-foot modular system that makes inner tubes and automatic spreading more efficient.

The internal head is composed of a double arrangement of bearings, which provide greater control of the rotational forces that are transmitted to the internal barrel during cuts, preventing the internal barrel from rotating and premature clogging.

System of two inner tubes that allows to transport and manipulate the tube without disturbing the core, and to observe the most important sections of the core. It uses a connection system that cannot be unscrewed.

The half moon-shaped tube delivers up to 20% more usable core and offers the downhole geologist the ability to perform a visual inspection without damaging the core.

The On Ice type tube has two thin sleeves chemically treated so that the friction forces are reduced to the maximum, avoiding the core to clog inside.

The spring-type Core Catcher is best suited for most core textures, as it consists of a wedge-shaped retainer inlaid with small particles of tungsten carbide inside.

It allows the sealing of the inner barrel without the need to waste time in the process of launching the internal flow diversion ball.

Provides ideal development of the run because it maintains a constant supply of clean lubricant that is not contaminated by drilling mud.

The core is scraped or marked by blades located inside the bottom section of the Barrel. This marking system consists of three blades, each marking a longitudinal slot as the core moves up into the inner aluminum tube.

- The design of the crowns increases the life, improves recoveries and optimizes the quality of the core.

The Spiral Blade technology ensures the best stabilization of the crown. - The Radial Bearing prevents any lateral movement of the inner barrel.

- The Thrust Bearing provides efficient rotational independence between the inner and outer barrel.

- The controlled spacing guarantees a minimum flow in the throat.

Provides ideal development of the run because it maintains a constant supply of clean lubricant that is not contaminated by drilling mud.

Surface handling

Improper handling on the surface can cause irreversible damage to the recovered cores, meaning that the samples cannot subsequently be analyzed in the laboratory, which is why our surface handling equipment is of high quality together with a team of specialized professionals.

Stabilization with lithotarge: It is a stabilization system developed to protect the core during handling in transportation, which is implemented by injecting a foam that enters in a liquid state, through holes made along the aluminum tube, expands and solidifies in the ring that is located between the core and the aluminum tube, protecting and immobilizing the sample and thus avoiding damage.

Advantage:

- Does not cause core damage.

- It does not invade the nucleus.

- Does not create fractures or propagate existing open fractures. Holds core under pressure surges 2 to 4 psi.

- It is an international industry standard.

- The Lithotarge is invisible to CT scanners.